Slow production hampering your growth? These automated workhorses achieve 200-1,000 prints/hour with perfect repeatability.

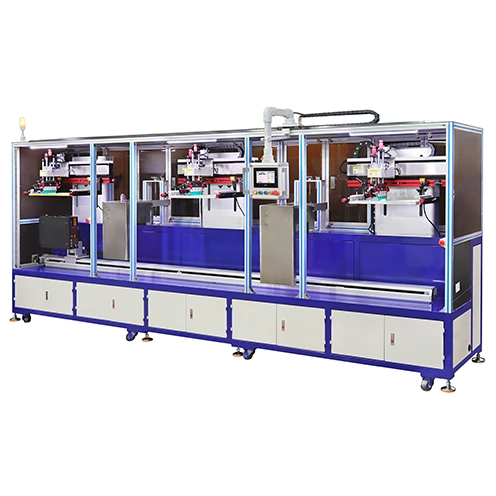

The fully automatic flat bed screen printing machine delivers industrial-scale textile/package printing at 90% reduced labor costs while maintaining ±0.2mm registration accuracy through robotic precision and intelligent ink management systems. They eliminate manual errors while quadrupling output.

Three revolutionary impacts:

60% faster than manual screen printing

75% less ink waste with automated control

98% uptime with self-cleaning mechanisms

Need production-grade printing without the labor headaches? Here's the technology transforming industrial printing.

These systems combine robotic substrate handling, auto-registration, and programmable multi-color printing to produce flawless graphics on flat materials at speeds up to 1,200 cycles/hour without operator intervention.

Core automation features:

Auto-loading conveyors move materials precisely

Vision alignment systems ensure 50μ accuracy

Servo-driven squeegees control ink deposition

UV curing tunnels instantly dry prints

Standard configurations:

Print area: 40×60cm to 120×160cm

Colors: 1-12 station models

Speed: 200-1,200 prints/hour

Still using manual presses? These innovations explain why smart factories are upgrading.

Modern automatic screen printer integrates self-registration, predictive maintenance alerts, and IoT connectivity to achieve 24/7 production with less than 1% defect rates and real-time quality monitoring.

Breakthrough technologies:

| Feature | Manual Machines | Automatic Machines | Advantage |

|---|---|---|---|

| Setup Time | 45-90 minutes | <5 minutes | 95% faster |

| Daily Output | 500-800 prints | 5,000-10,000 prints | 10x capacity |

| Ink Consumption | 15-20% waste | 3-5% waste | 75% savings |

| Staff Required | 3-5 operators | 0.5 FTE monitoring | 90% reduction |

Smart factory integration:

Cloud-based job tracking

Automated thickness control

Self-diagnosing maintenance

Remote troubleshooting

Wasted hours on setup and reprints? Automation slashes production costs while boosting quality.

By eliminating manual plate alignment and ink mixing, automatic screen printers reduce changeover time from 1 hour to under 7 minutes while maintaining consistent 1.5μ dot gain across 100,000+ prints.

Efficiency metrics by industry:

Output: 850 t-shirts/hour vs. 150 manually

Registration: 0.3mm accuracy for multi-color designs

Ink Use: 40% reduction with auto-dosing

Speed: 1,200 boxes/hour with perfect CMYK alignment

Waste: 90% fewer misprints

Uptime: 22 hours/day production

Throughput: 800 metal panels/shift

Durability: 10,000+ washes resistance

Automation: Direct ERP integration

Overwhelmed by technical specs? Match these key factors to your production needs.

Select machines based on substrate size (S/M/L), required print quality (100-400 mesh), and automation level - entry-level units start at $25,000 while full production lines reach $300,000 with 12-18 month ROI.

Selection matrix:

<1,000 prints/day: Semi-auto models ($25k-$60k)

1,000-5,000 prints/day: Standard automatics ($80k-$150k)

>5,000 prints/day: Custom high-speed lines ($200k+)

Auto registration (vision systems preferred)

Quick-change frames (under 2 minutes)

Integrated drying (UV/IR/heat options)

Material handling (vacuum beds/loaders)

Industry-specific recommendations:

Fabric printers: Choose oval machines for stretch materials

Electronics: ESD-safe models for circuit boards

Promotional items: Multi-color carousel systems

Fully automatic flat bed screen printers from haover represent the future of industrial printing - delivering unprecedented speed, precision, and cost savings while handling today's most demanding production volumes with flawless consistency.